What is a frosted glass

One of the most widely used glasses in the market are frosted glasses.

One of the most widely used glasses in the market are frosted glasses.

Usually, due to the unique advantages of frosted glass, the market for the production and sale of this type of glass is particularly prosperous.

One of the most important advantages of frosted glass is creating privacy, controlling light and heat, and beautifying the environment.

In this article from the JamImen blog, we are going to talk about the concept of frosted glass and then the methods of making frosted glass.

Also, we will introduce you to two types of sand blast and satin glass.

Stay with us.

What is a frosted glass? | How is frosted glass made?

Opaque glass refers to glass that significantly reduces light transmission due to its opaque or non-transparent surface.

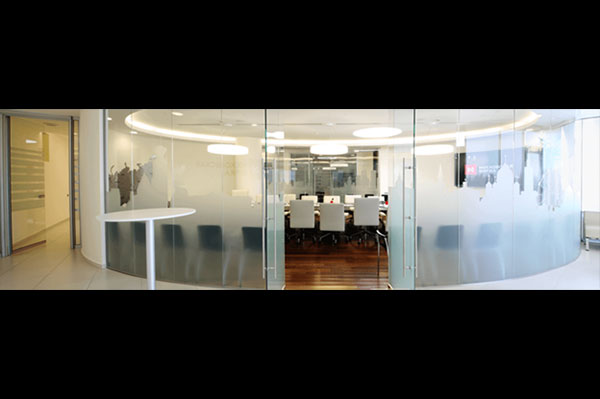

Frosted glass is used as a popular solution in interior and exterior design of buildings, commercial spaces and public places. Among the common uses of frosted glass, it can be mentioned in doors, windows, and wall glass.

The method of making frosted glass How is frosted glass made?

Maybe you are also curious about how frosted glass is made. You should know that the production of frosted glass is a secondary process in glass production.

In other words, first the normal (transparent) glass is made and then, using auxiliary techniques and tools, the opaque is added to it.

In general, there are two basic methods for making frosted glass, which we will mention below.

Sandblasted frosted glass | The method of making sandblasted glass

The sandblasting method is one of the common methods of matting glass.

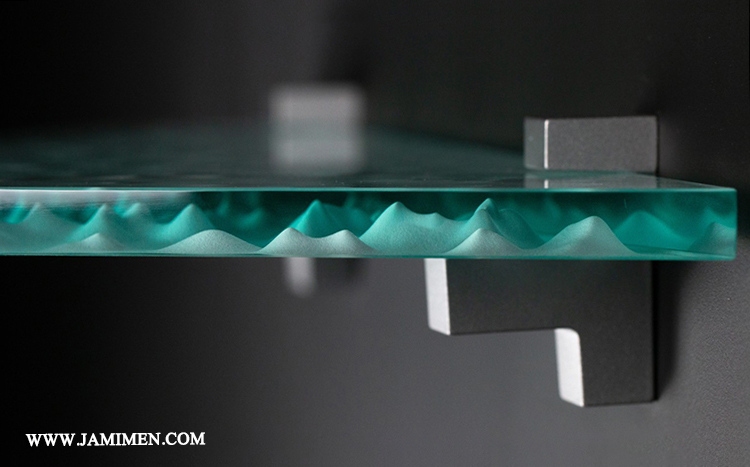

The concept of sandblasting refers to creating engravings and designs on glass.

Sandblasted matte glass is divided into two types, matte or semi-matte.

In semi-opaque glass, sand is not sprayed on all parts of the glass.

Therefore, parts of the transparent glass are transparent.

In matting the glass with the help of sandblasting, sand is sprayed on the glass with high pressure, then a thin surface of the glass is removed and the opaque glass is created.

To make sandblasted glass, in industrial centers of glass making, using nozzles, the process of spraying sand on the surface of the glass is done.

Sandblasted Tempered glass

One of the most famous types of glass is tempered glass. To learn more about this type of glass, be sure to read the article on the advantages and disadvantages of tempered glass.

An important issue is sand blasting in tempered glass.

If the tempering process is done by sandblasting, the output obtained is a blast glass with tempering properties.

But if this is on the photo, that means the sandblasting process is done first, then we will no longer have tempered glass.

Disadvantages of sandblasted glass Checking frosted glass

Sandblasting method can be used to make all types of glass opaque.

But this method also has disadvantages. Frosted glass may be cracked in this way.

On the other hand, the price of frosted or sandblasted glass is higher than normal glass.

The advantages of sandblasted glass

Using sandblasted glass, in addition to beautifying the surrounding landscape, has other advantages for you, such as:

- Long service life of sandblasted glass

- The quality of the matte glass in the door is excellent

- It is possible to engrave special designs on frosted glass

Making matte satin glass What is satin glass?

Satin glass is another method for matting glass, which has many similarities with the sandblasting method.

In the preparation of satin glass, a solution made with fluoric acid is used.

This solution is poured on the surface of the glass, which turns the glass surface from clear to opaque.

Some believe that the output of the matte glass production process with satin is of higher quality compared to sandblasting.

Advantages of using satin glass | Benefits of satin matte glass

In the following, we will introduce you some advantages of satin glass

as follows:

- Satin glass is used in the cover of some special lamps due to its ability to distribute light evenly.

- Satina glass is an ideal choice for environmentalists due to the possibility of recycling.

The price of sandblasted glass Cheap frosted glass

Determining the price of frosted glass depends on various factors.

One of the most important factors determining the price is the type of glass, layout, quality of the factory, and the color used.

In general, the cost of glass sandblasting is more than the original price of glass.

The unit of calculation and transaction of glass is based on "square meter".

Disadvantages of satin glass

This type of glass cannot be cut or reshaped.

When making satin glass, you must carefully implement the desired design and shape. Also, due to the increase in temperature, there is a possibility of cracking.

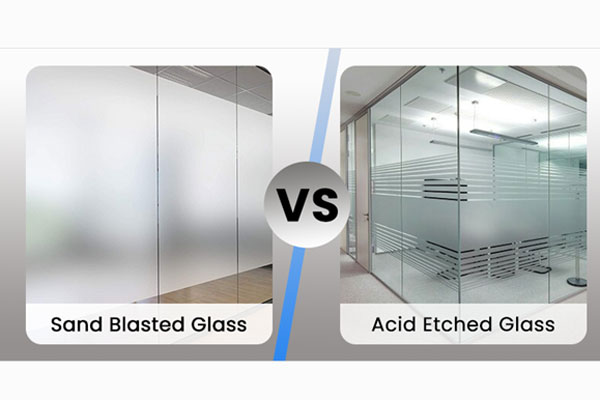

The difference between sand blast and satin glass

One of the most important differences between these two glasses is related to their degree of opacity.

In sandblasted glass, we have a semi-opaque coating that largely prevents the back of the glass from being seen, but still a little of the contents behind the glass may be visible.

Satin glass, on the other hand, has a completely opaque surface, and does not allow any spots to be seen through the glass.

Therefore, sandblasted glass is used for decorative purposes, decorative panels and all kinds of panels.

The main use of satin glass is in interior walls, doors and windows. Also, satin is used more in places like the bathroom where privacy is more important.

Another important difference is the thickness of frosted glass.

Conclusion

The use of frosted glass is very common and ideal due to its beauty, helping to maintain privacy and temperature stability.

JamImen glass factory produces luxury glass products to beautify the environment with the help of experienced workers and using the latest glass making technologies.

By contacting JamImen consultants, get a free consultation and

Buy high-quality frosted glass.