A Phenomenon Called Glass Suicide

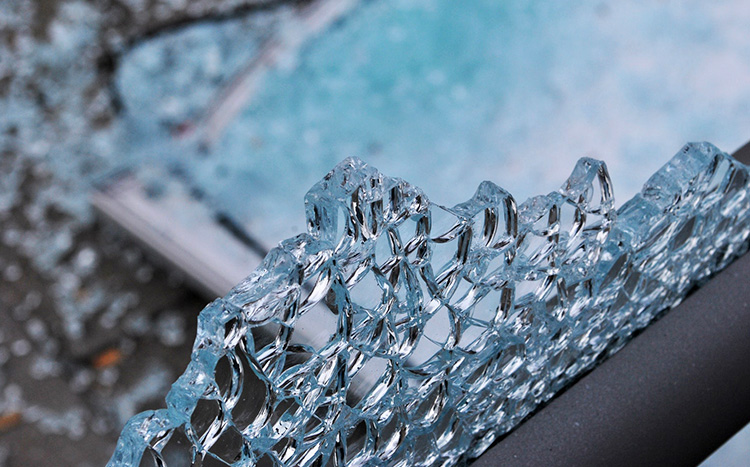

Glass Suicide, you may have encountered a situation in your industry where tempered glass suddenly breaks in your hands, on the pallet, or even after installation without being touched, and it seems to us to be broken without any apparent reason.

Causes and Prevention Methods

You may have encountered a situation in your industry where tempered glass suddenly breaks in your hands, on the pallet, or even after installation without being touched, and it seems to us to be broken without any apparent reason.

In many cases, we don’t know the reason for these sudden breakages, and it often leaves us perplexed and uncertain.

Today, we aim to investigate the reasons behind the sudden breakage of tempered glass and discuss prevention methods.

Tempered or safety glass is widely used in the construction, automotive, household appliance industries, and various other industrial applications due to its high resistance to impact and heat. However, one phenomenon that can occur with tempered glass is known as “glass suicide.” This term describes the sudden and unexpected shattering of tempered glass, even when no apparent external pressure is applied. This phenomenon not only causes safety issues but also leads to additional costs for replacing broken glass. In this article, we will define glass suicide, explore its causes, and discuss prevention methods.

What is Glass Suicide?

Glass suicide refers to the sudden and spontaneous breakage of tempered glass without any external physical factors, such as impact or pressure. In many cases, glass that appears to be perfectly intact suddenly shatters into small fragments without warning. This type of breakage occurs due to the internal stresses and impurities within the tempered glass, which can lead to such a phenomenon. When this happens to large glass panels or glass installed at high elevations, it can pose significant safety and financial risks.

Causes of Glass Suicide

Nickel Sulfide Inclusions

One of the primary causes of glass suicide is the presence of nickel sulfide inclusions in the glass structure. Nickel sulfide is a chemical compound that remains as an impurity within the glass during the raw glass manufacturing process. These small particles can expand due to temperature changes and internal stresses, which, after the tempering process, cause internal cracks in the glass, ultimately leading to sudden breakage. Nickel sulfide forms at high temperatures and gradually changes phase during the cooling process. This phase change can increase internal stress within the glass and eventually cause breakage. Even if these particles are extremely small, they can still significantly impact the stability of the glass, leading to glass suicide. Unfortunately, these impurities are invisible and undetectable in raw glass, which presents significant challenges for tempered glass manufacturers.

Thermal and Mechanical Stresses

Due to the rapid cooling process during tempering, tempered glass retains internal stresses. In fact, one of the key differences between tempered and raw glass is the retention of these stresses and stored energy within the core of the glass. If these stresses are not properly managed, they can lead to sudden breakages. Tempered glass is typically produced at high temperatures and then rapidly cooled to achieve high strength. However, if there is even a small error in temperature settings during this process, or if the glass is not cooled properly, the internal stresses can increase beyond acceptable levels, raising the risk of glass suicide. Furthermore, if tempered glass is exposed to extreme temperature fluctuations (such as rapid heating and cooling) without undergoing proper heat treatment processes, it can result in increased stress and eventual breakage. This issue is especially common in glass installed on building facades, where the glass is exposed to direct sunlight during the day and cold temperatures at night.

Internal Pressure

Tempered glass, due to its internal stresses, is also prone to additional pressure. These stresses can increase if the glass is installed incorrectly. For example, if the glass is subjected to uneven mechanical pressure during installation, the internal stresses can increase, leading to breakage.

This issue is often observed in glass that has been improperly installed or mounted in unsuitable frames.

Previous Physical Damage

Small damages or micro-cracks that occur during transportation or installation may gradually grow over time and lead to sudden breakage. These damages may initially seem minor, but as time passes and internal stresses build up, they can result in glass suicide.

Prevention Methods for Glass Suicide

If the cause of glass breakage is related to thermal stresses or installation issues, glass suicide can be prevented by adopting appropriate measures in the production process, reducing thermal stresses, and improving the installation process. However, if nickel sulfide is the cause of glass suicide, the only effective prevention method is the use of the “heat soaking” technique.

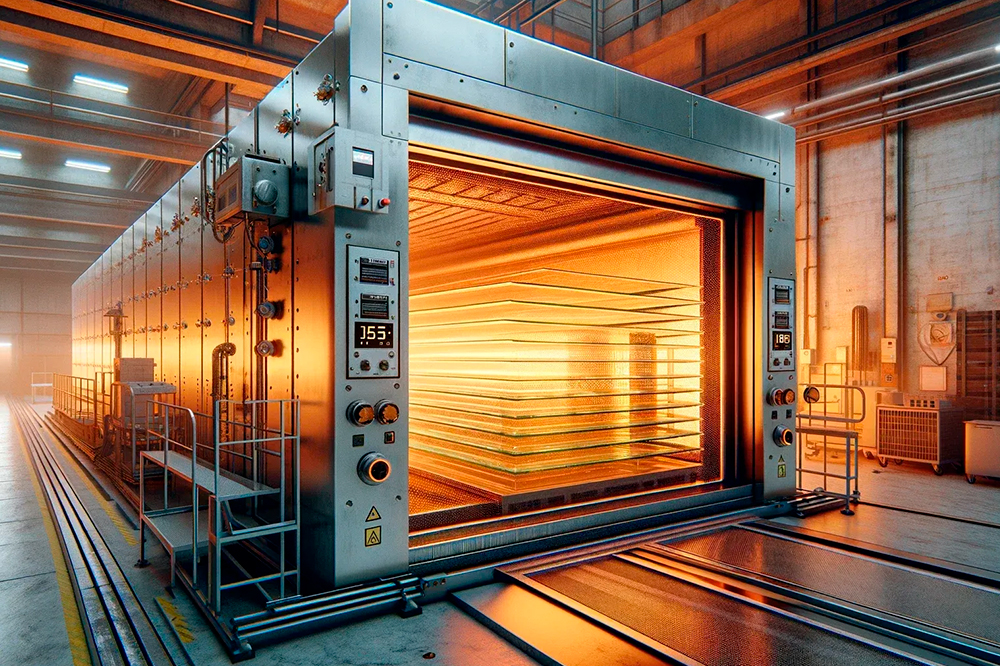

Heat Soaking Process:

Heat soaking is one of the most effective methods for preventing glass suicide. This process is specifically designed for tempered glass and aims to eliminate nickel sulfide inclusions and reduce internal stresses within the glass. In this method, the tempered glass is placed in a special heat soaking furnace and subjected to high temperatures for several hours. The temperature is carefully controlled to trigger phase changes in the nickel sulfide particles, eliminating potential internal stresses within the glass.

This process effectively “tests” the glass in a controlled environment, causing any potential breakages to occur inside the furnace rather than after installation in the real-world environment. This process is particularly recommended for glass used in sensitive locations such as high-rise buildings or glass bridges.

Quality Control in Production:

Another method to prevent glass suicide caused by thermal stresses is to improve production processes and implement more stringent quality control. Using high-quality raw materials free of impurities, maintaining precise temperature control in furnaces, and adhering to production standards can help prevent this phenomenon.

Proper Glass Installation:

Proper glass installation is another crucial factor in preventing glass suicide. Tempered glass should be carefully installed by experienced technicians to avoid uneven pressure on the glass. Using appropriate frames and ensuring proper spacing in the design can help reduce the risk of glass suicide caused by improper installation and design.

Conclusion:

Glass suicide is a complex phenomenon in the tempered glass industry that can be caused by nickel sulfide inclusions, internal stresses, or physical damage. However, with techniques like heat soaking, improved quality control in production, and proper glass installation, the occurrence of this phenomenon can be minimized. Implementing these measures can help reduce the risks and costs associated with sudden glass breakage, while also ensuring greater safety and durability for glass products.

Limitations of Using Heat Soaking Furnaces in Iran:

While heat soaking furnaces are one of the most effective methods for preventing glass suicide worldwide, access to this technology is limited in Iran. Many domestic glass manufacturers cannot afford the high costs associated with acquiring and operating these furnaces. As a result, Iranian manufacturers must rely on alternative quality control methods and process optimization to minimize the risks of glass suicide. However, because nickel sulfide inclusions cannot be detected or removed, the risk cannot be entirely eliminated.

Jamimen’s Commitment to Quality in the Tempering Process:

Jamimen Glass Manufacturing Company, utilizing advanced technology and precise production processes, has managed to control all stages of tempered glass production with high accuracy. Despite the limited access to heat soaking furnaces in Iran, the company has continuously adjusted its processes to prevent the formation of thermal stresses in the glass. This includes precise temperature control in furnaces, regular cooling, optimization of furnace fans, and the use of high-quality raw materials.

With a commitment to quality and safety, Jam Imen has become one of the leading producers of tempered glass in the country. We have consistently strived to produce durable and high-quality products that meet global standards, using innovative production methods, advanced systems, and skilled labor to ensure the satisfaction of both domestic and international customers.

Choosing Jamimen means choosing security, quality, and expertise.