What Is Sandblast Glass

In the previous articles, we talked in detail about frosted glass and frosted glass types. Now, in this article, we are going to talk specifically about sandblasted glass.

What is sandblasted glass? | Buying sandblasted glass

In the previous articles, we talked in detail about frosted glass and frosted glass types. Now, in this article, we are going to talk specifically about sandblasted glass.

Most people know frosted glass as sandblasted. On the other hand, the supply and demand market of this glass is one of the most prosperous markets in the glass industry.

Join us to tell you more about the concept of sandblasted glass, how to make this glass, and the uses of sandblasted glass in this article.

What is sandblasted glass | How is sandblasting made?

Sandblast glass is one of the most common decorative and frosted glass in the market. Due to the unique applications of this type of glass, it can be used in many homes, educational or office environments, etc.

But to learn more about sandblasted glass, it is better to examine the concept of sandblasting itself.

The sandblasting process is not only for glass production and is also used in various other industrial uses. In general, the sandblasting process is defined as:

A type of sandblasting in which the metal surface is cleaned by spraying a high-pressure stream of sand or other abrasive material.

In English, they call the process of abrasive blasting.

In the sandblasting process, the abrasive sands, which are mainly made of silica and metal oxides in different sizes, are accelerated using the air pressure of the compressor and are sprayed on the surface of the part.

Applications of sandblasting | Using sandblasted glass

Apart from the sandblasting process, sandblasting has other types such as:

Wet blasting, grit blasting, shot blasting, vacuum blasting, soda blasting, brush blasting, ice blasting, etc.

Each of the above spraying methods are used in various industrial methods and in working with various materials such as glass, metal, wood, paper, MDF, etc.

But in this article, our intention is to further investigate the sandblasting process in glass production.

Using sand, you can complete the process of sandblasting, rust removal, and painting the internal and external surfaces of the parts or polishing them.

Other applications of sandblasting include cleaning all kinds of industrial molds, roughing the surfaces of parts (with the help of special abrasives) for optimal glazing and Teflon work for durability and better quality.

Sandblasting also prepares the surfaces of the parts to be done

A variety of decorative, industrial, or color plating are used.

Carving texts and various reliefs and digging or embossing them on MDF, glass, tile, and ceramic surfaces, which are mostly used for advertising and decorative purposes, are other uses of sandblasting.

The history of sandblasting Inventor of Sandblast

The discovery of the sandblast method has its own strange story. It is known that one day Benjamin Tilghman, who was a military general, was spending time in his military headquarters located in a log cabin.

Suddenly, a huge sand storm appears; This sand storm was one of the strangest storms in the history of that region.

After the storm is over, Mr. Tilghman wants to look out of his room window when a trivial issue draws his attention from the sand storm to the window glass of the room; The glass of the room is frosted due to impact with sand particles from the storm, and this is the reason for awakening the sparks of Mr. Tilghman's curiosity.

Therefore, the idea of making a device that can throw sand particles on the surface of the parts at high speed is formed in his mind.

The first sandblasting machine was invented by Tilghman and earned the title of the father of sandblasting in the world.

With this important invention, the old method of cleaning and preparing surfaces, which was expensive and very time-consuming in many cases, was abandoned, and a new method called sandblasting was introduced to the world as an economical and convenient process.

Would you like to know more about glass?

To know the latest price of tempered glass and interesting facts about the origin of tempered glass:

Read this article from Jam Imen's blog: What is Sekurit glass?

The method of making sandblast glass

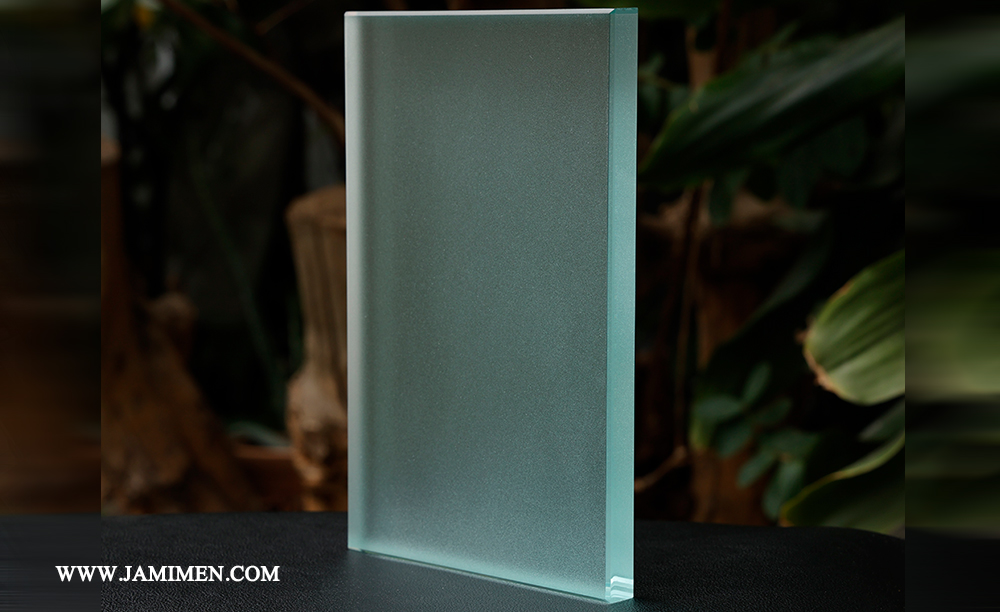

Sandblasted glasses are created by high-pressure spraying of a special type of sand and gravel by a sandblasting machine.

The main use of sandblasting is to create special designs and to make glass opaque; During sandblasting, any type of design can be implemented on sandblasted glass.

In other words, the sandblasting process is the process of spraying sand on the glass with high pressure and high speed, the explanation is that the sand particles affect the glass and remove a very small volume from the glass surface.

Types of sandblasted glass models

Due to the differences in how sandblasted glass is made, various types of this glass can be found in the market.

In the following, we will introduce some famous examples of sandblasted glass to you, so that you can make the best choice according to your needs and budget.

Types of sandblasted glasses include:

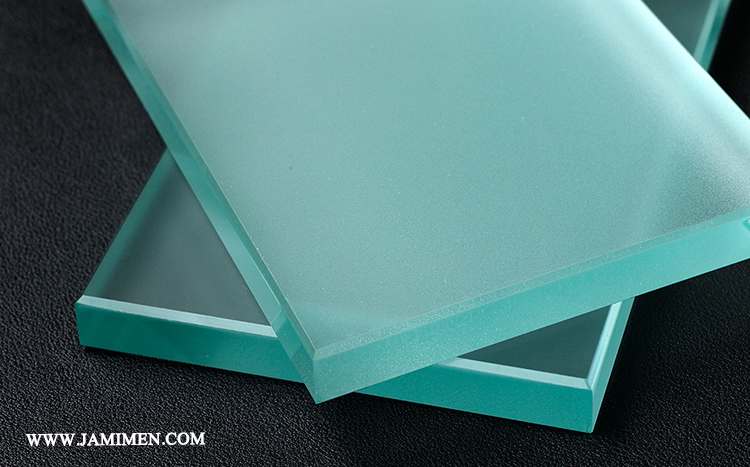

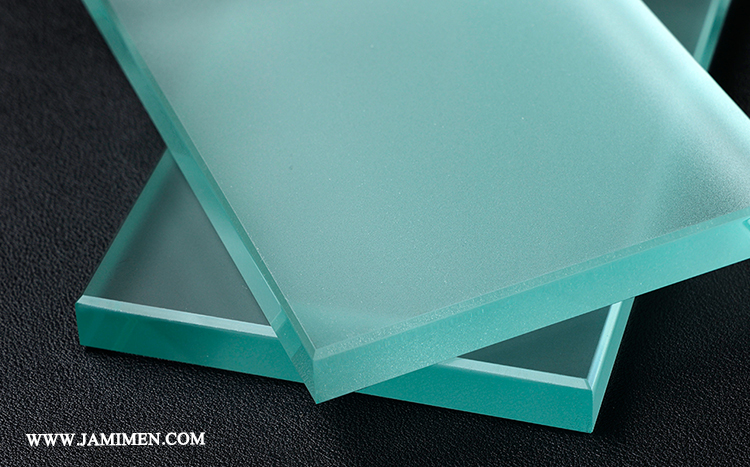

1- Full matte sandblasted glass

The popular type is sandblasting. The main use of this glass is in bathrooms, partitions and generally places where privacy is very important to you.

To make this glass, they usually use tempered glass. In such a way that these glasses are subjected to sand spraying operation in an integrated form by the sandblasting machine.

After finishing the sandblasting process, the surface of these glasses is completely opaque and it is impossible to see the images behind the glass.

Due to the popularity of this privacy glass, it is an excellent choice for government offices and companies looking to secure and privatize their privacy.

2-Sandblast patterned glass

One of the best methods of advertisement and interior decoration of home and company is to use glasses with a favorite design or relevant logo.

The implementation of the sandblasting process is such that at first the relevant design or logo is designed with the help of graphic software such as Photoshop.

Then these designs are printed on special adhesives using special cutter plotters.

Then these patterned adhesives are engraved on the glass by a skilled force during the sandblasting process.

In general, the logo on the glass can be highlighted in two ways: matte background or glass background, in places where proper visibility is required, only the logo is sandblasted, if the rest of the glass is still smooth and has the ability to transmit light.

3- Matte sandblasted road glasses

One of the most beautiful types of glass is sandblasted glass!

This type of glass is usually used in partitions and special decoration spaces; Also, the size of the distance between the matte road lines can be different according to the customer's order.

Frosted glass is a type of glass that has regular vertical and horizontal lines on the glass.

Also, special checker designs are usually used in the production of frosted road glass.

What do you know about multi-glazed windows?

Would you like to get interesting information about the uses and the best producers of this type of glass?!

So be sure to read this article from Jam Imen's blog:

The price of sandblasted glass | Buy glass online

To buy sandblasted glass and determine the right price, it is necessary to pay attention to some points.

One of the most important factors affecting the price of glass is the manufacturer of the glass and the quality of the materials used in making the glass.

Some Iranian glass manufacturing factories launch low-priced products on the market, but in the end, due to the use of low-quality materials in the glass production process or glass sandblasting, the mentioned glasses are of very poor quality.

Another important factor in determining the price of glass is its size and thickness.

You should choose the right size according to your needs; Naturally, the thicker the glass, the higher the price.

Currently, one of the most famous manufacturers of sandblast glass is Jam Imen Company.

With years of experience in producing all kinds of best-selling and widely used glass, this group is ready to sell sandblasted glass with the best quality and the most suitable price.

Why sandblasted glass is safe? | Buy safe cup glass

The production of all kinds of glass, including frosted glass, sandblasted glass, satin glass, etc., is done in Jam Imen factory.

If you want to buy a high-quality sandblasted glass, so that it will last you for years in terms of impact and heat resistance, you can try the sandblasted glasses of Safe Jam.

The production process of sandblast glass in this factory is carried out with the help of modern foreign devices; Also, the presence of skilled human forces in the process of quality control and glass manufacturing gives you a guarantee of excellent quality.

In the following, we mention some other advantages of ordering Jam Imen sandblasted matte glass:

- Guaranteeing the quality of glass resistance against temperature and pressure

- Providing special discounts in case of bulk purchase from Jam Imen

- Reasonable and economical price compared to other market options

- Providing free expert advice before placing an order

- Using the best devices and high-quality materials in the sandblasting process

If you intend to buy glass from Jam Imen Company, you can contact Jam Imen through the contact section or phone number 02151067 to receive expert advice or place an order.

What is your opinion about the use of frosted glass and sandblasting? Have you ever had the experience of using these glasses? We are waiting for your comments!