What Is Tempered Glass

Tempered glass, often referred to as safety glass, is a specialized type of glass that undergoes a distinct heat treatment process to enhance its strength and safety attributes.

10/6/2023 5:26:44 PM

5181

The use of glass is continuously increasing in today's world. Glass is a versatile and unique material that, despite its transparency, offers many features and greatly enhances the appearance of products.

At Jam Imen Manufacturing Group, located in Tehran/Iran, we have been providing glass products for various applications for over 25 years, aiming to improve the quality of life. Our services cater to the needs of various industries and reputable building and industrial manufacturers in the glass sector. By delivering superior quality products, we have become one of the leading business partners in the global household appliances and construction industries. Jam Imen Glass Manufacturing Group responds to the highest level of demand in creating aesthetics and unique products for household appliances. The experts at Jam Imen, with their positive and constructive experiences, are ready to provide you with valuable products from the glass industry. Our skills and expertise allow us to meet your expectations in this field.

In this regard, we aim to clearly and transparently explain the stages of tempered glass production in this article to give our customers a better understanding of the glass industry. Before discussing the tempered glass production process, we will briefly explain glass production to provide a better understanding of this material.

What is glass, and how is it made?

Glass is a material created by melting a series of rocks and minerals (which are processed and turned into powder before melting) in special furnaces at temperatures ranging from 1200 to 1500 degrees Celsius.

Main raw materials of glass:

The main raw materials needed to melt and produce glass include:

- Silica: The main and most crucial component, making up the largest portion of glass.

- Sodium carbonate: Facilitates the melting process in glass production.

- Lime: Increases glass resistance to water penetration.

- Feldspar: Acts as a regulator in the composition of glass. In addition to these primary raw materials, other ingredients such as gypsum, sodium sulfate, sodium nitrate, and arsenic are added to the glass mixture before melting.

Glass production process:

These materials are mixed in appropriate proportions, heated in a furnace at 1500 degrees Celsius, and melted. The molten material is then transferred to a section called a tin bath, where it floats on tin, which is why raw glass manufacturers are also known as float glass producers. Since the molten materials float on the tin, there is always a layer of tin on one side of the glass. When entering the tin bath, the temperature of the molten materials ranges between 1200 and 1500 degrees Celsius, and by the time they exit, the temperature drops to around 650 degrees Celsius.

The appearance of the material as it exits resembles a solid ribbon. In the next stage, this solid ribbon passes through a layer, slowly cools down, and glass is formed. Finally, the formed glass is cut using diamond blades into raw glass sheets in various sizes according to market needs. In the Iranian glass industry, float glass or raw glass manufacturers are considered upstream or primary industries, while tempered glass manufacturers are considered auxiliary industries. Thus, the tempered glass industry is classified as a complementary and auxiliary industry to the main float glass industry.

What is tempered glass?

The term “tempered glass” refers to heat-treated glass and comes from the English word "Security," meaning safety. In English, it is also called "Tempered Glass," meaning heat-treated glass, because after being produced, raw glass is exposed to additional heat treatment to increase safety.

Therefore, the process of reheating glass to strengthen it is called tempering, and tempered glass refers to glass that has undergone heat treatment to enhance its safety.

With this definition, we can clearly say that at Jam Imen Glass Manufacturing Company, we source float glass either domestically or internationally and produce it according to the customer's requirements, delivering it as tempered (safety-enhanced) glass.

The difference between raw glass and tempered glass The main differences between tempered glass and non-tempered (or raw) glass are:

- Strength:

Tempered glass is significantly more resistant to impact and mechanical pressure than raw glass. If broken, tempered glass shatters into small, blunt pieces, whereas regular glass breaks into large, sharp shards that can pose serious risks to human safety.

- Safety:

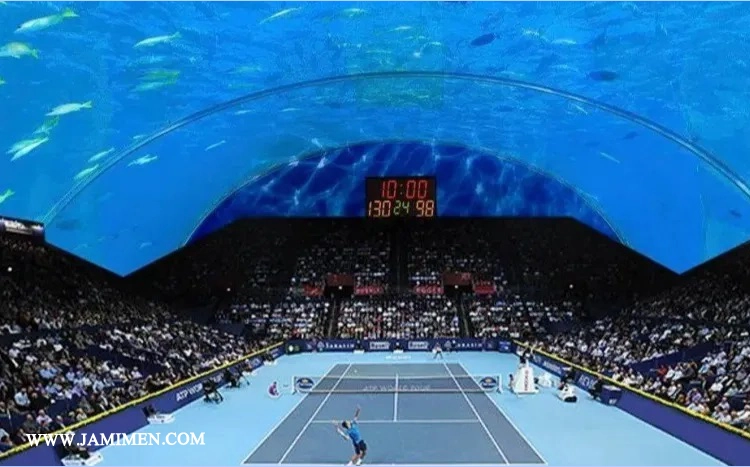

Due to its high impact resistance, tempered glass is suitable for environments that require enhanced safety, such as cars, buildings, and various industries. In contrast, regular glass breaks easily and creates hazards for users and bystanders.

- Heat and sound insulation:

Tempered glass offers superior thermal and sound insulation compared to regular glass, reducing heat and sound transmission through the glass and increasing comfort and efficiency in spaces.

- High-temperature resistance:

Tempered glass can withstand higher temperatures and is more resistant to temperature fluctuations. This makes it ideal for use in hot and sunny environments, such as building facades, and in industries where products are exposed to temperature changes, like home heating and cooling appliances. In summary, tempered glass is a strong and safe alternative to raw glass and is preferred in many applications.

The tempered glass production process:

Due to its unique stability against thermal shock, temperature changes, and mechanical loads such as bending and impact, Jam Imen’s tempered glass is a desirable product for many applications. With our wide range of glass processing and strengthening machines, we can produce products that meet your specific needs and are suitable for a variety of uses. The processes we can apply to our glass are diverse, and at Jam Imen, we are ready to offer services that cater to every taste and requirement.

If we are to explain the production stages of a tempered glass in a standard and orderly manner, they can be categorized as follows:

Stages of tempered glass production:

- Cutting

- grinding, Diamond edging (edge processing)

- Beveling(side surface finishing)

- Drilling or embedding (creating holes in the glass as per customer requests)

- Printing

- Heat treatment (tempering)

- Multi-layer processing

- Quality control

- Packaging

The tempering (heat treatment) process is the final stage in the production of tempered glass, and it’s important to know that once glass comes out of the tempering furnace, it can no longer be cut or drilled.

Additionally, depending on your design, the glass you request may go through all of these stages or only a few specific processes during production.

Jam Imen Glass Manufacturing Group

Jam Imen Glass Manufacturing Group responds to the highest level of demand in creating aesthetics and unique products for household appliances and the construction industry. The experienced professionals at Jam Imen are ready to provide you with valuable products from the glass industry. Our skills and expertise enable us to meet your expectations in this field.

In this regard, since 2008, alongside meeting domestic customer needs, we have significantly increased production and exported a large volume of various glass products to reputable companies in Bulgaria, Serbia, Turkey, Russia, Iraq, Pakistan, Tajikistan, and Uzbekistan. We always exceed customer expectations by offering professional services and fulfilling our commitments to meet customer needs. Our specialists work according to defined standards to ensure that, in addition to your satisfaction, your product remains competitive and stands out in the market.

With our skills and expertise, we deliver products that you can trust for their outstanding quality.

Jam Imen – A Safe Choice

Related posts