World Class Safety Glass

Laser drilling is one of the most advanced and precise glass drilling technologies

The process of loading glass products at Jam Imen Company employs three distinct methods, each tailored to the specific characteristics...

We have no limits in packing products. Packing in JAM IMEN is done based on the design desired by the customer.

With complete knowledge of the products and by analyzing them day and time during the manufacturing and final product phases based on international standards and the customer’s request, the quality control team is always on the scene to make sure of the appearance and technical quality of the

After cutting and grinding the glass, the multi-glazed process starts, which includes cutting, injecting desiccants and applying Butyl sealant to the spacer, washing the glass, assembling the spacer and the glass (two or three panes), pressing, injecting, and ultimately secondary sealant.

The coating process is done after the tempering using fully automated vacuum machines through magnetron sputtering in different thicknesses and designs.

Heat treatment (tempering) is carried out using advanced furnaces with the knowledge of experienced personnel in flat and bent states as per international standards.

The printing process is done through the silk method and with fully automated and semi-automated machines, with highest quality.

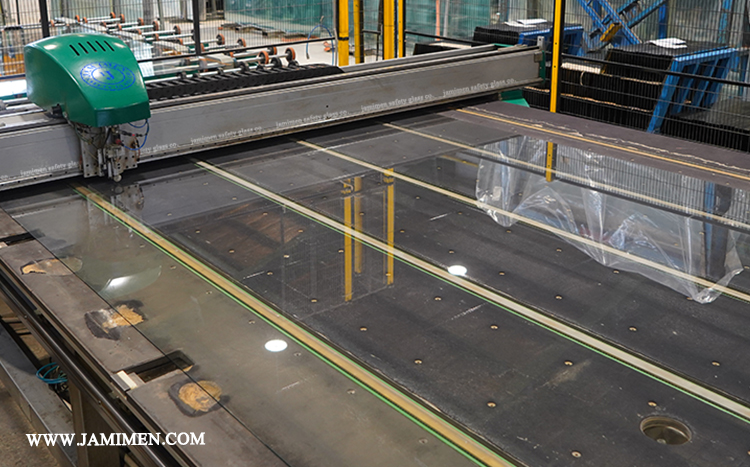

The internal cutting of glass or geometric forms can be done using water-jet or master CNC cutting This is done with the shape and size requested by the customer, with high precision, and fully automated with a specific file.

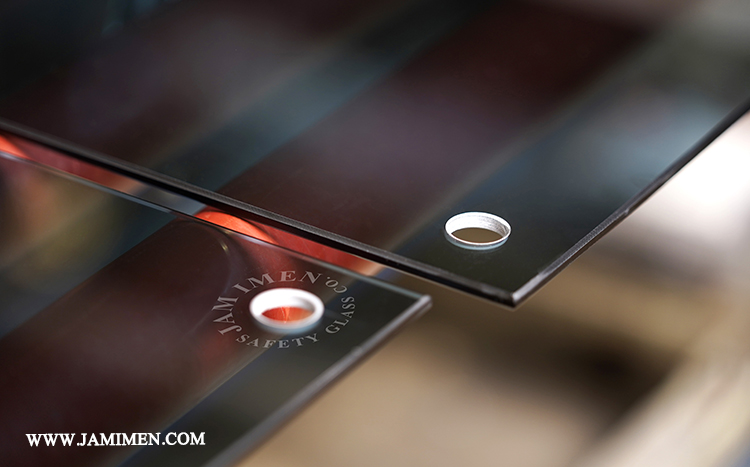

The drilling process is fully automated, using vertical and horizontal CNC machines.

The grinding process is conducted in geometric and simple forms, using horizontal and vertical grinding machines and Italian CNC with high quality and precision.

Glass Fabrication

The cutting process is conducted using Italian CNC machines with the ability to move in three X, Y, and Z axes. This is fully automated through the CNC cutting program prepared by the Engineering Technical Unit in 3mm to 20mm thicknesses.