Glass Fabrication

Glass Fabrication

Cutting

The maximum possible dimensions are 4000×3210

With precision and tolerance of ±0.15mm

Able to scan the paradigm and convert it to a CNC file

Cutting of all types of geometric and complex forms

Fully automated cutting line, without manual intervention

Accessible panes, colored ,reflective, transparent, and Iranian satin glass , Iranian super-clear glass, Low-E and European ultra-clear glass

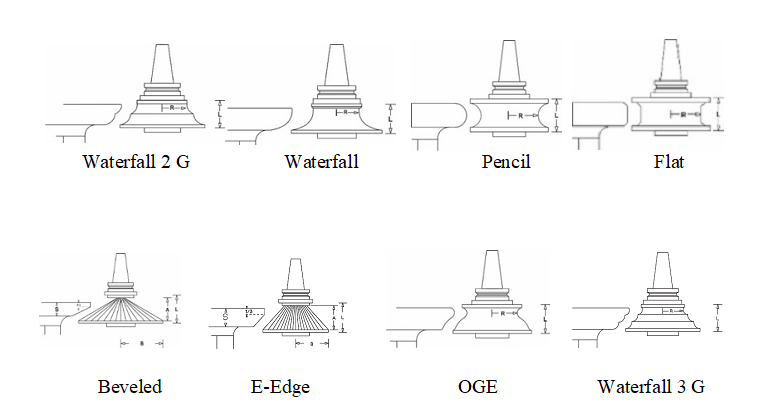

Grinding and Beveling

5mm to 50mm beveling

Radius , diagonal, and flat edges in different dimensions

Drilling

Possible hole diameter ranges from 6mm to 60mm

The minimum distance from the edge of the hole to the edge of the glass, and the distance between the edges of the two adjacent holes must be twice the thickness of the glass

Laser cutting

Laser cutting is one of the most advanced and precise glass cutting technologies, utilizing a powerful laser beam. In this process, laser energy is concentrated on a specific point, generating high heat that melts, burns, or vaporizes the material exposed at the desired point. Compared to traditional methods such as mechanical cutting with diamond or waterjet cutting, laser cutting offers greater precision and quality. It cuts glass with high accuracy and produces very smooth, polished edges without requiring physical contact.

Laser machines are widely used due to their ability to cut and drill with extreme precision, particularly for creating very small holes, even less than a millimeter in size. This feature is critical for industries that require precise and delicate holes, such as glass for projectors or various panels in built-in ovens, range hoods, and switchboards. Machines like waterjets are suitable for thicker and larger cuts, but they cannot create very small holes or complex inlays with the accuracy and delicacy that laser technology provides.

The minimum dimensions for glass that requires laser processing are 50 millimeters by 50 millimeters, and the maximum dimensions are 900 millimeters by 600 millimeters. Additionally, the minimum diameter for inlays achievable by this machine is less than one millimeter, and the maximum diameter is 90 millimeters for glass thicknesses between 4 and 8 millimeters.

Jamimen Company, with an environmentally friendly approach, is the first importer of laser cutting machines specifically designed for indoor glass environments in Iran. The company has always strived to upgrade its production processes and technologies to offer a higher level of product quality, based on customer demands and the changing quality preferences of its business partners.

Unlike other machines in the tempered glass manufacturing industry, the company's laser cutting machines do not require water consumption and do not generate noise pollution or environmental waste (such as silica residue). For this reason, they simultaneously reduce the negative environmental impact of the production process while providing better quality.

In summary, the main advantages of laser cutting compared to other methods are its high precision and speed, clean and smooth cutting surfaces, and the ability to create holes and inlays with complex shapes, especially in advanced manufacturing processes that require such precision.

Water-jet and master CNC cutting

Unlimited shapes

High precision and low tolerance

High quality and delicacy

Engraving on the glass

Beveling on shape glass

Printing

Equipped with a lithography machine and a room for developing negative and stencil films with the finest fabrics of SEFAR, SAATI, and MBC brands, and German sensitive emulsion

A wide range of colors

Scratch-resistant and organic ceramic colors

More than 10,000 delicate and precise designs

A minimum 0.5mm line thickness and a minimum 0.5mm point diameter

Printing on both sides of the glass, printing on the front and printing on the back of one glass

Flat and Bending tempering

Consistent high quality of the glass surface in terms of appearance

Fragmentation of up to 200 fragments (higher than the standard), with extremely high safety If requested by the customer

High thermal shock

Impact resistance up to 7 times the ordinary glass (raw)

Paint curing with the glass and its consolidation on glass

Minimum possible bend radius for a minimum width of 600mm and a maximum width of 2400mm is 1100mm

Minimum possible bend radius for a minimum width of 400mm and a maximum width of 900mm is 500mm

Approved in all the relevant standard tests

20to 200N/mm3 pressure resistance

Able to bend the glass into A and B states

Coating

Uniform coating

Able to adjust the coating percentage, light direction, or light blocking

Based on the customer-requested design

Multi-Glazed Glass

(Low-E glass can be used (to control the heat transfer

Glass and spacer of different thicknesses

In tempering and raw states

Maximum dimensions of 3200×2800

Able to multi-glaze bent and flat glass

High-quality sealant and spacers

Double-glazed U-channel glass with special silicone sealant

Pure Argon and drop in the window’s U-factor

The Quality Control Team

Controlling the products in terms of appearance, dimensions, and tolerance

Conducting functional tests

The Fragmentation test (up to 200 fragments based on the customer’s need)

The thermal shock tests

The impact resistance test (Able to pass the IK08 test, Standard: IEC60068-2-75)

According to Standards EN 12150 and BS 03193

The Fragmentation Test

The number of particles counted in the tested glass within a 50×50mm square is 60

The Thermal Shock Test

The thermal shock test on the manufactured products is conducted based on their applications and on the assumption that the product has been assembled accurately and according to the standard

The Impact Test

The impact resistance of glass depends on its assembly, size and thickness, impact type, impact intensity, and many other parameters

Packing

Wrapping the products in cellophane

Using high-quality paper dividers and foams between the glasses

Three-tier pallets by the carpentry unit of JAM IMEN

Shrink packing of one or more sheets of glasses together

Durable and reliable packing

Loading of Industrial and Decorative Glass

Loading of Packaged Building Glass

In the second method, the focus is on larger glass products, such as building glass, which is carefully packaged in specialized glass carriers for secure transportation. This method is also applicable to glass products like shower cabins, which are enclosed in wooden boxes. Given the larger dimensions of the packaging for this category of products, loading is carried out using overhead cranes

Loading of Unpackaged Building Glass

The third loading method is reserved for tempered glass employed in building construction. These glasses are produced individually and are not packaged in carriers or boxes due to their diverse dimensions and thickness. For this category, loading is carried out using specialized glass transport vehicles, specifically Langendorf vehicles equipped with glass carriers. The process requires the utmost precision and is performed by the skilled personnel of Jam Imen Company using special metal handles. Negligence or imprecision in this process may result in visual defects, including scratches, dents, or breakage of glass corners. Proper manual loading is a highly specialized task, involving precise arrangement of glass dimensions and careful handling during placement in the vehicle. Entrusting this task to experienced individuals minimizes the risk of accidents and potential hazards. Despite the inherent durability of tempered glass against impacts, there is still a possibility of glass breakage if loading and transportation are not executed with due care. To mitigate these risks, the company's trained personnel utilize special cotton pads in sensitive areas of the glass and install plastic corner protectors on all four corners of the glass to prevent any incidents that may result in scratches, dents, or glass corners breakage during the loading process