Temperli cam nadier

Günümüzde cam kullanımı sürekli olarak artmaktadır. Cam, şeffaf olmasına rağmen birçok özellik sunan, çok yönlü bir malzemedir ve ürünlerin görünümüne ekstra güzellik katar.

6.10.2023 17:26:44

5561

Günümüzde cam kullanımı sürekli olarak artmaktadır. Cam, şeffaf olmasına rağmen birçok özellik sunan, çok yönlü bir malzemedir ve ürünlerin görünümüne ekstra güzellik katar.

Biz, Tahran/İran'da bulunan Jam Imen üretim grubu olarak, 25 yılı aşkın bir süredir, cam ürünlerini farklı alanlarda kullanıma sunarak yaşam kalitesini artırmayı hedefliyoruz. Hizmetlerimiz, camla ilgili çeşitli sektörlerin ve saygın inşaat ve sanayi üreticilerinin ihtiyaçlarını karşılamaya yöneliktir ve üstün kalitedeki ürünlerimiz sayesinde, şu anda dünya çapında ev aletleri ve inşaat endüstrisinin önde gelen ticaret ortaklarından biri olarak tanınmaktayız.

Jam Imen Cam Üretim Grubu, ev aletleri için benzersiz estetik ve ürünler yaratma konusundaki en yüksek talebe yanıt vermektedir.Jam Imen'de bir araya gelen uzmanlar, deneyim ve becerileriyle, cam sanayisinin değerli ürünlerine sahip olmanızı sağlamak için hazırdır. Yetkinliklerimiz ve uzmanlığımız, bu alandaki beklentilerinizi karşılamamıza olanak tanır.

Bu bağlamda, müşterilerimizin cam endüstrisi hakkında daha fazla bilgi sahibi olmalarını sağlamak için temperli cam üretim aşamalarını açık ve şeffaf bir şekilde bu makalede açıklamayı amaçlıyoruz. Temperli cam üretim sürecini anlatmadan önce, cam üretimi hakkında kısa bir açıklama yaparak bu malzemeyi daha iyi anlamanıza yardımcı olacağız.

Cam nedir ve nasıl yapılır?

Cam, bazı taşlar ve minerallerin (eritmeden önce işlenip toz haline getirilen) özel fırınlarda 1200 ila 1500 santigrat derece sıcaklıkta eritilmesiyle oluşan bir maddedir.

Camın ana hammaddeleri:

Cam eritme ve üretiminde kullanılan ana hammaddeler şunlardır:

Silis:Silis, camın ana bileşeni olup en önemli ve en büyük kısmını oluşturur.

Sodyum karbonat: Cam üretim sürecinde sodyum karbonat, erimeyi kolaylaştırır.

Kireç: Camı suya karşı dayanıklı hale getirir.

Feldspat: Camın bileşiminde bir düzenleyici olarak görev yapar.

Bu hammaddelerin yanı sıra, eritme işleminden önce cam karışımına alçı taşı, sodyum sülfat, sodyum nitrat ve arsenik gibi diğer maddeler de eklenir.

Cam üretim yöntemi:

Bu maddeler uygun oranlarda karıştırılır ve 1500 santigrat derece sıcaklıkta fırına aktarılıp eritilir. Eritilen malzemeler fırından sonra kalay banyosu adı verilen bir bölüme taşınır ve kalayın içine yüzer şekilde bırakılır. Bu nedenle, ham cam üreticilerine yüzer cam ya da flot cam üreticileri denir. Eritilmiş malzemenin kalay banyosuna girişi sırasında sıcaklığı 1200 ila 1500 santigrat derece arasında değişirken, çıkışında sıcaklık 650 santigrat dereceye düşer.

Malzemeler çıkışta katı bir şerit şeklini alır.

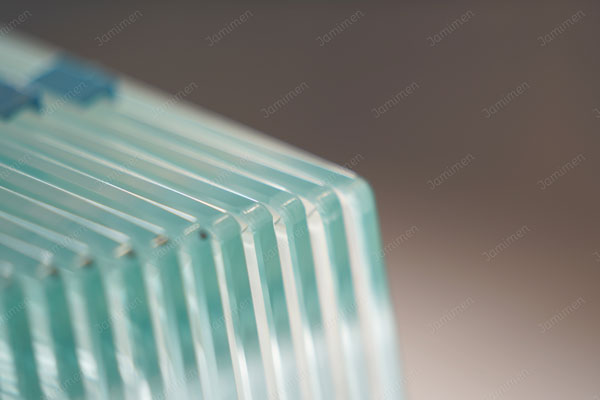

Bir sonraki aşamada bu katı şerit, bir tabakadan geçirilerek yavaş yavaş soğutulur ve cam oluşur. Son olarak, üretilen cam, elmas bıçaklarla kesilerek, pazardaki ihtiyaca göre farklı boyutlarda ham cam levhalar halinde kesilir.

İran'daki cam endüstrisinde, flot cam veya ham cam üreticilerine üst düzey sanayi veya ana sanayi, temperli cam üreticilerine ise yan sanayi denir. Bu nedenle, temperli cam üretimi, flot cam sanayisinin tamamlayıcı ve yan sanayisi olarak kabul edilir.

Temperli cam nedir?

Temperli cam kelimesi, İngilizce'deki (tempered) kelimesinden türetilmiştir. Temperli cam, aslında güvenli hale getirilmiş, yani kırılmaz hale getirilmiş cam anlamına gelir. İngilizce'de temperli cam, "Tempered Glass" olarak adlandırılır, bu da camın üretildikten sonra güvenlik için tekrar ısıtılması, yani pişirilmesi anlamına gelir. Bu nedenle, camın güvenlik için tekrar ısıtılmasına temperleme denir. Temperleme, bir işlem olarak kabul edilir ve bu işlemle güvenli hale getirilmiş cam, temperli cam olarak adlandırılır.

Bu tanımlara göre, Jam Imen'de üretilen plaka camları, iç veya dış pazarlardan temin edip, müşteri taleplerine göre üretip temperlenmiş (güvenli hale getirilmiş) cam olarak teslim ettiğimizi açıkça söyleyebiliriz.

Ham cam ve temperli cam arasındaki fark Temperli cam ile temperlenmemiş ya da ham cam arasındaki temel farklar şunlardır:

Dayanıklılık: Temperli cam, darbelere ve mekanik basınçlara karşı ham camdan çok daha dayanıklıdır.

Kırıldığında, temperli cam küçük, keskin olmayan parçalara ayrılırken, normal cam büyük ve keskin kenarlı parçalara ayrılarak insan hayatı için ciddi tehlikeler oluşturabilir.

Güvenlik: Yüksek darbe direnci nedeniyle, temperli cam otomobiller, binalar ve çeşitli sanayiler gibi daha yüksek güvenlik gerektiren ortamlarda kullanılmaya uygundur. Buna karşılık, normal cam kolayca kırılır ve kullanıcılar ile çevredeki insanlar için ciddi tehlikeler yaratabilir.

Isı ve ses yalıtımı: Temperli cam, normal camdan daha iyi ısı ve ses yalıtım özelliklerine sahiptir. Bu, camdan ısı ve ses geçişini azaltarak ortamın konforunu ve verimliliğini artırır.

Yüksek sıcaklıklara dayanıklılık:

Temperli cam, yüksek sıcaklıklara dayanıklıdır ve sıcaklık değişikliklerine karşı daha fazla direnç gösterir. Bu, özellikle güneşli ve sıcak alanlarda, binaların cephelerinde ve sıcaklık değişimlerine maruz kalan ev aletleri gibi ürünlerde kullanım için önemlidir. Genel olarak, temperli cam, ham cam için güçlü ve güvenli bir alternatif olarak tercih edilir ve birçok uygulamada kullanılır.

Temperli cam üretim süreci: Temperli camın benzersiz termal şok direnci, sıcaklık değişiklikleri ve bükülme ve darbe gibi mekanik yükler karşısındaki dayanıklılığı sayesinde, Jam Imen'in temperli camları birçok uygulama için ideal bir üründür.

Çeşitli cam işleme ve güçlendirme makinelerimizle, her türlü cihaz ve farklı uygulamalar için ihtiyaç duyduğunuz ürünleri üretebiliriz. Cam üzerinde uygulayabileceğimiz işlemler oldukça çeşitlidir ve biz Jam Imen olarak her zevk ve ihtiyaca uygun hizmet sunmaya hazırız. Temperli cam üretim sürecini standart ve sıralı bir şekilde açıklayacak olursak, şu adımları sıralayabiliriz:

Temperli cam üretim aşamaları

• Kesim

• rodajlama , Elmaslama (camın kenarlarının işlenmesi)

• bizote Kenar işleme (camın kenar yüzeyinin işlenmesi)

• delik Delme ve yerleştirme (müşteri isteğine göre camın içine delikler açma)

• Baskı •

Isıl işlem (temperleme)

• Çok katmanlı hale getirme

• Kalite kontrol

• Ambalajlama , paketleme

Genel olarak, temperleme (ısıl işlem) temperli cam üretim sürecinin son aşamasıdır ve temperleme fırınlarından çıkan camın artık kesilemeyeceğini veya delinemeyeceğini bilmek çok önemlidir. Tasarımınıza göre cam üretim sürecinde tüm bu aşamaları veya sadece belirli işlemleri gerçekleştirebiliriz.

Jam Imen Cam Üretim Grubu, ev aletleri ve inşaat sektörü için benzersiz ürünler ve estetik yaratma konusundaki en yüksek taleplere yanıt vermektedir. Jam Imen'de bir araya gelen uzmanlar, olumlu ve yapıcı deneyimleriyle, cam endüstrisinin değerli ürünlerini size sunmaya hazırdır. Becerilerimiz ve uzmanlığımız, bu alandaki beklentilerinizi karşılamamızı sağlar. Bu doğrultuda, 2008 yılından bu yana üretimi artırarak ve iç pazarın taleplerini karşılayarak, Bulgaristan, Sırbistan, Türkiye, Rusya, Irak, Pakistan, Tacikistan ve Özbekistan gibi ülkelerdeki saygın firmalara büyük miktarda cam ihraç etmeyi başardık.

Müşterilerimizin beklentilerinin ötesine geçiyor ve profesyonel hizmetler sunarak, taahhütlerimize sadık kalarak müşterilerimizin ihtiyaçlarını karşılıyoruz. Bu yolda, tüm uzmanlarımız tanımlanmış standartlara uygun olarak çalışıyor ve hem sizin memnuniyetinizi sağlamak hem de ürününüzün piyasada rekabet edebilir ve parlak olmasını sağlamak için çaba gösteriyor.

Becerimiz ve uzmanlığımızla, parlak kalitesine güvenebileceğiniz bir ürün sunuyoruz.

Jam Imen – Güvenli Seçim

İlgili Mesajlar